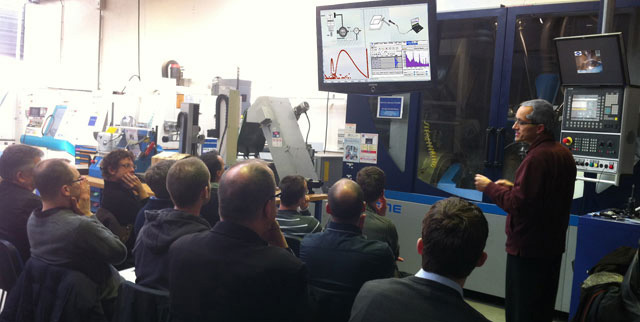

Learning the ChatterMaster method

The ChatterMaster® method has received the special prize of the innovation competition at the French Industry Exhibition, Lyon 2011.

With the ChatterMaster method and software, your company become autonomous to diagnose and optimize all machining vibrations issues.

ChatterMaster is based on natural language and it is a very powerfull tool in companies. It is also used in public schools for training technicians.

Training on site

First level of training (very easy techniques) :

- First theoretical notions on machining vibrations

- Simulation and measurement of static stiffnesses, natural frequencies, damping factor, and optimal cutting condition calculation.

- Analysis on the cases choosen by the client.

=> The trainees will be able to diagnose and methodically react in front of the machine-tool.

Second level of training :

- Theoretical notions on machining vibrations

- Measurement and analyze of machining vibrations signals

- Measure and analyse of spindle and axis vibrations.

- Measure and analyse of radial cutting force (because it is the fundamental source of machining vibrations)

- Analysis on the cases choosen by the client.

Recommendend measurement equipments :

- Microphone : “blue snowflake” (from Amazon, ≈80€).

- Manual dynamometer 300 Newtons (≈160€ from : http://www.metil.be/pdf/sn-fr.pdf).

- Long stroke micrometric dial gauge (≈150€ from Mitutoyo, n° 513-425-10E).

- 1 or 2 accelerometers 8776A50M6 (sensitivity 100mV/g) (≈500€), 8452A (magnetic base) (≈140€), 8436 (standard base) (≈25€), 8432-5 (glue wax), BM-174-6 (cable) (≈45€, more lenght of cable +≈60€), + maybe 8778A500 (miniature sensor for small tool tap testing, 10mV/g) (≈790€) + maybe Kistler-8786A5 (≈650€) (high sensitivity sensor for axis machine analysis), from www.kistler.com

- USB signal conditionner “PLUG-n- DAQ Lite” (≈1000€) from www.roga-instruments.com

- 1 or 2 suitcase : https://www.amazon.fr/Brubaker-professionnelle-Entièrement-Modulable-aluminium/dp/B001NI6D3G, or : pelicases ≈ 250€ from www.abylon.fr

- Free Audacity software : https://www.audacityteam.org

=> The trainees will be able to precisely diagnose and methodically react using all the possibles techniques.

Expertise on site

Example of expertise program :

- Half day for preliminary analysis and measure preparation :

- Analysis of your documents (machines, tools, workpieces), recorded signals or sounds, analysis of previous studies made.

- Planning the measurement day.

- One day for mesures :

- Stiffness (machine axis, tool, tool-holder, workpiece, workpiece holder)

- Frequencies (natural static frequencies, during rotation, during mouvements, during machining, etc.)

- Damping coefficients.

- Cutting forces.

- One day for analysis and synthesis.

- Diagnosis.

- Solutions definition.

- Debriefing meeting and discussions, about results and solutions to be applied.

- All machining parameters are taken into account.

- All possible solutions are studied in detail.

Examples of possible obtained solutions :

- Defect on a machine element (spindle, machine axis, tool holder, workpiece holder, etc.).

- New cutting conditions (rotational speed, engagement, machining strategy, etc.).

- Tool modifications (cutting angle, variable pitchs, damper, etc.).

Legal notice

ChatterMaster.com software and vibraction.fr website is edited by

Dr Lionel ARNAUD,

Phone +33 6 22 96 64 90,

Hosting :

1&1 internet AG, Brauerstr. 48, 76135 Karlsruhe, Germany,

represented in France : 1&1 Internet SARL,

French SARL with «capital de 100 000 euros», address :

7 place de la gare, BP 70109, 57201 Sarreguemines Cedex,

registered « au Registre du Commerce et des Sociétés »,

as : RCS Sarreguemines B 431 303 775,

Directors of publication are : Markus Huhn and Robert Hoffmann

contact : http://assistance.1and1.fr/contact or phone : 0970 808 911.

Web site: www.1and1.fr

Contact

Address : UTTOP, 47 avenue d'Azereix, 65000 Tarbes, France.

Lionel ARNAUD : +33 6 22 96 64 90

lionel.arnaud@vibraction.fr

Page 2 of 2